Some researchers from the University of Bergamo carried out an accurate analysis of our production system.

To know the results download the pdf.

System description

THE PRODUCT

Comagricola Green Europe deals with the production, packaging and marketing of professional turf mixes.

The diversification of the choice of essences for the composition of the various mixtures is agreed with specialised agricultural institutes and the consultancy of agronomists to obtain a product perfectly suited to customer requests and to obtain maximum adaptability to the different soil and climatic conditions or intended uses.

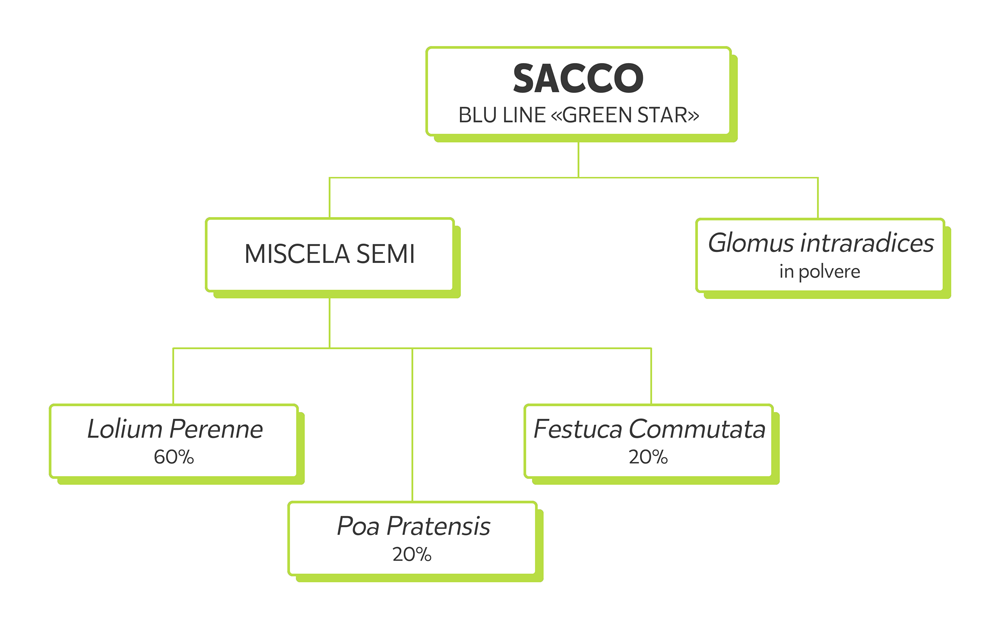

There is also the possibility of enriching the mixture with the addition of microorganisms.

THE BASE LIST

Generally, all the mixtures are composed of a minimum of 3 to a maximum of 6 essences or varieties and enriched by specific microorganisms that improve the process of planting and growth of the product.

By way of explanation, we report the basic list of one of the best-selling products among those made in the company.

THE PRODUCTION PROCESS

The production department is made up of a highly automated and constantly evolving production line to obtain maximum quality performance.

Workers have the task of checking the bill from the sales office and preparing the varieties and quantities required on the machine for inputting material in the production system.

System classification

Technological Axis

Process production

The highly automated single-machine process follows the obligatory cycle of mixing, enrichment, weighing, bagging, sewing and packaging.

Market Axis

Repetitive production to order

The product is differentiated by bag size and mixture composition.

The customer can request customisations for their order, both in terms of the composition of the mixture and in the graphics of the packaging

Production on forecast

To provide a rapid and punctual service, Comagricola Green Europe gives absolute priority to customer orders.

During the off-season, the production process is concentrated on restoring stocks of the products in the catalogue intended for sale in the following season (winter over spring – summer over autumn).

Management Axis

Intermittent batch production

Large bags containing single essence turf seeds are used in the production. The different types contained in the primary packaging are placed on the ground intermittently, depending on the essences used, to obtain a pre-mixing.

The finished product packages are then stored in the warehouse ready for delivery or to be subsequently sold.

Wortmann Classification

Comagricola Green Europe mainly adopts a Make-To-Order approach giving the highest priority in the production process.

The products in the catalogue are always in stock, as well as the raw materials that compose them, and are always available to satisfy customised requests.

The total production of turf mixes for ornamental and sports use is around 300,000kg.

In low season Comagricola produces material with a Make To Stock approach, always giving priority to customised requests from any customers.

Type of process

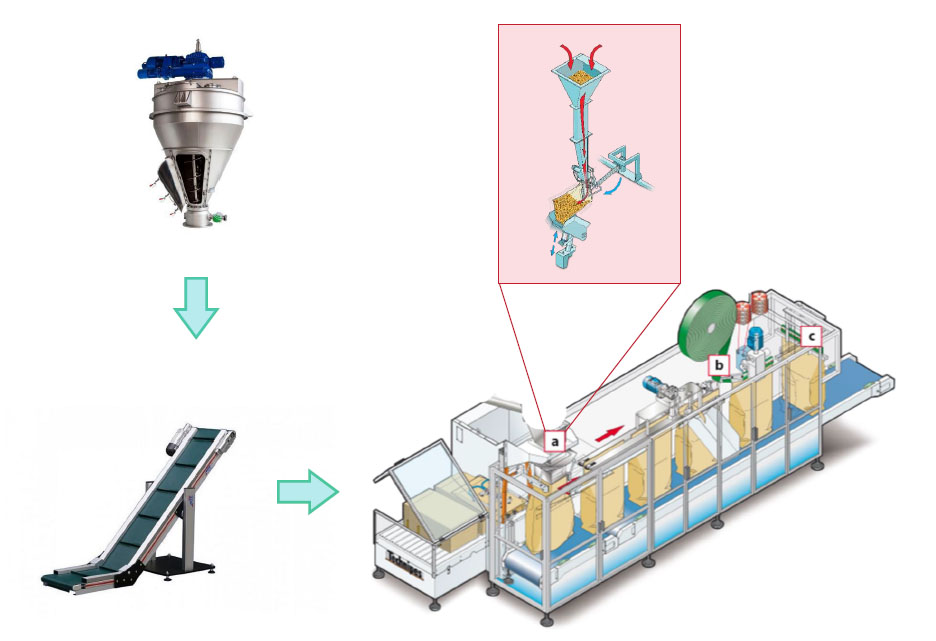

The process takes place on a highly specialised production line for mixing and packaging turf mixes.

The plant, completely made in Italy, consists of a mixer, conveyor belt, loading hopper, electronic scale, bagging and sewing machine.

The most technologically complex part is that of bagging

- Bag blocking unit for Pinch Bottom bags, dosing bagging nozzle, bag inflation system, vibration system, check weigher

- Sewing head, thread cutting system, crepe paper system

- In-line gripper bag overturning system

System features

VOLUME, VARIETY, QUESTION AND CONTACT WITH THE CUSTOMER

VOLUME

HIGH – The plant is highly automated and allows high production volumes. The machine can produce up to 1500 bags/day of 10 kg

VARIETY

HIGH – The availability of various types of seeds allows you to create numerous mixtures of different composition

DEMAND

SEASONAL – Customer demand follows a seasonal trend with high peaks in spring and autumn

CONTACT WITH THE CUSTOMER

INTENSE – The customer is constantly at the centre of attention to satisfy specific requests

Internal performance

R: 1kg/5000kg

PRODUCTION CAPACITY

Theoretical: 1,500 bags/day

With two people: 900 bags/day

With one person: 600 bags/day

MINOR DOWNTIME

TDT = 60 min/day

(Value detected due to any adjustments such as bag drop or format change)

External performance

Total Lead Time: 3 days

FLEXIBILITY

PRODUCT: The company can introduce new products into production if requested by the customer

MIX: The company can easily change the type of product in production by introducing different seeds to be mixed between one batch and another

SERVICE

READINESS: High. Green Europe Comagricola can fulfil an order, even in terms of very high volumes, within 3 days. The waiting time for raw materials is practically zero as they are always available in stock

PUNCTUALITY: Green Europe Comagricola hardly delivers products late concerning the date communicated at the start of production

REGULARITY: Green Europe Comagricola always identifies exactly the delivery times of the finished product.

AVAILABILITY: Green Europe Comagricola can respond to requests for increased production

ASSISTANCE: Green Europe Comagricola provides on request a consultancy service to better adapt the order to the needs of customers